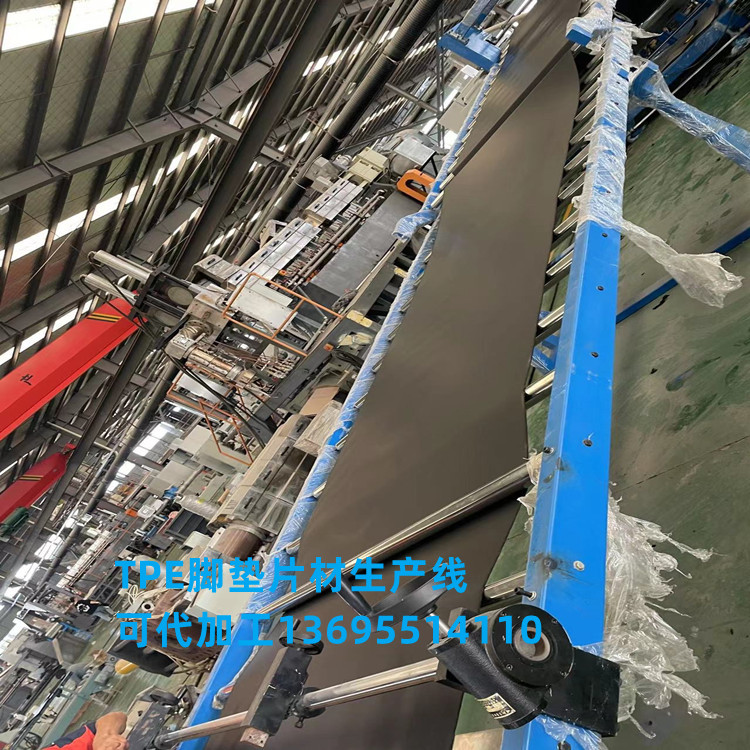

TPE片材代加工_TPE脚垫片材代加工_TPE高弹片材代加工

TPE汽车地垫为热塑性弹性体地垫,具有优异的耐磨性、耐划伤性、耐老化性和耐高温性,同时也易于清洁。它们是汽车内饰的重要组成部分。下面详细介绍一下TPE汽车地垫的性能特点和加工工艺。1、性能特点耐磨性:TPE汽车脚垫具有优异的耐磨性,可以承受长期的踩踏和摩擦,并保持其原有的形状和颜色TPE环保脚垫片材生产线http://121.43.145.37:99/api/preview/410/412/300。2. 耐划伤:表面硬度高,可抵抗一般划伤和划伤。3.耐老化:TPE材料稳定性好,不易氧化开裂,可长期使用。4. 耐高温:可在高温下使用,不易变形、变质。5. 易清洁:表面光滑,不易沾污,易于清洁和管理。2、TPE汽车脚垫的加工工艺包括以下几个步骤:1、材料制备:制备TPE原料及相关添加剂。2. 加热和熔化:加热和熔化TPE原料成流体状态。3.模具成型:将熔化的TPE流体注入模具中,形成所需的形状和尺寸。4. 冷却成型:对成型后的TPE脚垫进行冷却成型,使其达到所需的硬度和形状。5. 脱模:将冷却后的TPE脚垫从模具中取出。6. 表面处理:进行表面处理,如拉丝、打磨等,增加脚垫的防滑性和美观性。7. 包装检验:对生产的TPE汽车地垫进行质量检验,检验合格后包装出厂。综上所述,TPE汽车地垫在加工过程中具有生产效率高、成本低、环保等优点,使其成为汽车内饰件中的重要材料之一。

The performance characteristics and processing process of TPE automobile floor mats TPE automobile floor mats are thermoplastic elastomer floor mats, which have excellent wear resistance, scratch resistance, aging resistance and high temperature resistance, and are also easy to clean. They are an important part of automobile interior. The following is a detailed introduction to the performance characteristics and processing process of TPE car floor mats. 1、 Performance characteristics 1. Wear resistance: TPE car foot pads have excellent wear resistance, can withstand long-term stepping and friction, and maintain their original shape and color. 2. Scratch resistance: With high surface hardness, it can resist general scratches and scratches. 3. Aging resistance: TPE material has good stability, is not easy to oxidize and crack, and can be used for a long time. 4. High temperature resistance: It can be used at high temperatures and is not easily deformed or deteriorated. 5. Easy to clean: The surface is smooth, not easily stained, and easy to clean and manage. 2、 The processing process of TPE car foot mats includes the following steps: 1 Material preparation: TPE环保脚垫片材生产线http://121.43.145.37:99/api/preview/410/412/300Prepare TPE raw materials and related additives. 2. Heating and melting: Heat and melt TPE raw materials into a fluid state. 3. Mold forming: Inject the melted TPE fluid into the mold to form the desired shape and size. 4. Cooling and shaping: Cool and shape the formed TPE foot pad to achieve the required hardness and shape. 5. Demolding: Remove the cooled TPE foot pad from the mold. 6. Surface treatment: Conduct surface treatment, such as wire drawing, sanding, etc., to increase the skid resistance and aesthetics of the foot pad. 7. Packaging inspection: Conduct quality inspection on the TPE car floor mats produced, and package them before leaving the factory after passing the inspection. In summary, TPE car floor mats have the advantages of high production efficiency, low cost, and environmental protection during the processing process, making them one of the important materials in automotive interior parts.

13695514110

13695514110